Mechanical engg- Rotating Face Mechanical Seals:

Rotating Face Mechanical Seals:Mechanical seals are engineered for most pumps, mixer and agitator applications in maintenance. In many cases the designs have been proven to be workhorses over years of use. In others seals must be designed for evolving industrial demands.Mechanical seals deliver a full range or rotary configurations and component materials - to handle virtually and fluid moved by any equipment. When you specify engineered mechanical seals you have the advantage of the most advanced mechanical seal technology, the latest in field proven design and when working with an outside sales force there is hands on technical support. Rotating face units are the dependable mechanical seal answer for worn equipment when your shaft seals must be replaced. They are ideal for new equipment designs or to improve the usefulness of existing equipment by converting from pump packing to mechanical seals.

Mechanical seals feature:

*Invisible leakage In practical use, the basic rotating face mechanical seal principle is adaptable to serve a tremendous number of sealing needs: standard mechanical seals can suit most requirements-including temperatures to 500 degrees F and shaft speeds to 3600 RPM through the choice of secondary seal and the combination of seal and seat face materials which are offered. Seals can be ordered in balanced configurations to seal pressures above 200 psi, or used in a multiple for extremely high pressures or especially severe fluid services....Special mechanical seals can be furnished to meet the most demanding of industrial applications considering pressure, temperature, speed or fluid. Mechanical seal designs range from the work horse "single spring" mechanical seals, to highly engineered double cartridge seals for extreme applications. The basic of each type follows:

Single spring mechanical seals:Utilize a single spring coiled in a right of left hand design to accommodate left and right hand turning pumps. They have the flexibility to accommodate misalignment, shaft deflection, and break away shock loading. It resists clogging in extremely viscous fluids.

All mechanical seals are constructed of three basic sets of parts: 1) A set of primary seal faces: one that rotates and one that remains stationary. 2) A set of secondary seals known as shaft packings and insert mountings, such as o-rings, rubber boots, PTFE or Grafoil wedges, or V-Rings. 3) Mechanical Seals have hardware including gland rings, collars, compression rings, pins, springs, retaining rings and bellows.

|

|

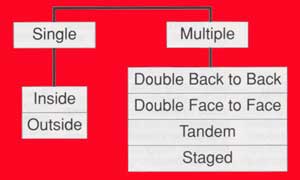

Mechanical Seals can be classified by Arrangement |

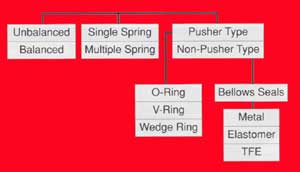

Mechanical Seals can be classified by Design |

|

|

|

A mechanical seal works though the use of two very flat (generally within 3 light bands flat) lapped faces which make it difficult for leakage to occur (beyond a vapor). As mentioned above one face is stationary and one rotates with the shaft. One of the two faces is usually a non-galling material such as carbon-graphite. The other will be a harder material providing dissimilar materials making contact and allowing one to be a sacrificial. The softer mechanical seal face usually has the smaller mating surface and is commonly called the "wear nose" of the mechanical Seal.

The Easiest seal to install as a replacement for pump packing is a cartridge type mechanical seal:

The Beauty of cartridge seals are they are self-contained. Holding all the elements of a mechanical seal set:

*Rotating Face Seal

*Stationary Seal face or faces

*Shaft sleeve

*Gland

Komentáře

Přehled komentářů

Kalu Industrial Co.,Ltd is specialized in mechanical seals.Cartridge seals,metal bellow seals,component seals,agitator seals are our main products.

Please contact us freely.

kalu@mechanicalsealschina.com

Asinoseal Co.,LTD

(Mechanical seals , 17. 4. 2014 10:34)Asinoseal Co.,LTD focused on mechanical seals,cartridge seals,metal bellow seals,component seals,www.asinoseal.com,contact us freely.

Mechanical seal

(KALU Industrial Co., Limited, 4. 7. 2016 5:45)